Technical Specifications

| Cardboard width, mm | 200-2400 |

| Cardboard thickness, mm | 2-11 |

| Min. reaming length, mm | 350 |

| Productivity, boxes/min | 3-6 |

| Number of preset templates, pcs | 40 |

| Number of longitudinal units, pcs | 6 |

| Number of transverse units, pcs | 1 |

| Min. distance between longitudinal knives, mm | 22 |

| Min. box height, mm | 18 |

| Types of cardboard | fanfold cardboard |

| Number of places for loading fanfold corrugated cardboard, pcs | 4 |

| Speed of movement of a cross knife, m/min | 60 |

| Speed of movement of longitudinal knives, m/min | 40 |

| Power, kW | 3 |

| Pressure in the pneumatic system, Bar | 6-7 |

| Dimensions (LxWxH), mm | 2500х1300х2500 |

| Weight, kg | 3200 |

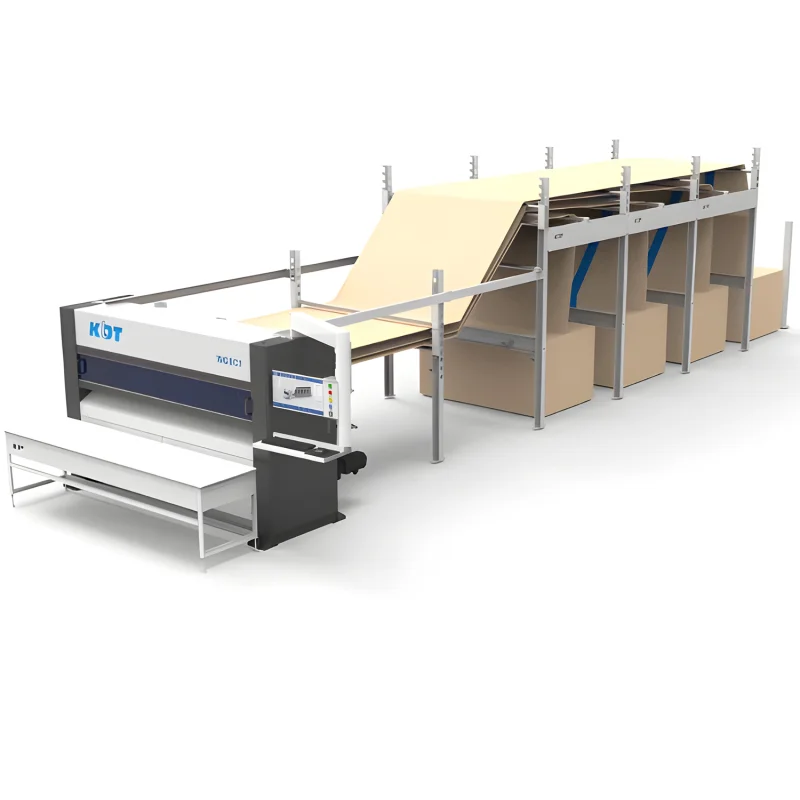

Cardboard box making machine WG8C1Z

Purpose :

Automatic cardboard box making machine for fanfold corrugated cardboard WG8C1Z is used in manufacturing enterprises of any level, enterprises providing special packaging services, using packaging of various sizes and designs. The equipment is designed to automate the packaging manufacturing process at your enterprise, to make it as simple and convenient as possible. With box making machine, you can manufacture any boxes for your products according to your requirements and the requirements of your customers.

Distinctive features :

Work with fanfold corrugated cardboard up to 2400 mm wide.

Control system - Intuitive control system based on industrial PC with touchscreen display and Windows OS. Complete production statistics and diagnostic system .

Box designer - Built-in editor and box designer. 40 templates in the program for creating standard boxes, as well as their import .

Corrugated cardboard feed stand - Special stand for storage and automatic feeding of fanfold corrugated cardboard for 4 places .

Corrugated cardboard feeding system - The machine software automatically calculates and selects the most appropriate format to minimize waste. Simultaneous loading of up to 4 corrugated cardboard formats .

Longitudinal cutting and scoring groups - The machine has 6 longitudinal cutting and scoring units. Each pair of disk knives simultaneously cuts and scorers the future box in the longitudinal direction .

Transverse cutting and scoring unit - The transverse cutting and scoring unit consists of a pair of disk knives. It performs cutting and scoring of the future box in the transverse direction .

Belt drive - Belt drive of the knife and shaft system .

Pressure rollers - The pressure rollers securely fix the corrugated cardboard in the cutting area .

Working as part of a line - The machine can operate both separately and as part of a production line .

Technical Specifications

| Cardboard width, mm | 200-2400 |

| Cardboard thickness, mm | 2-11 |

| Min. reaming length, mm | 350 |

| Productivity, boxes/min | 3-6 |

| Number of preset templates, pcs | 40 |

| Number of longitudinal units, pcs | 6 |

| Number of transverse units, pcs | 1 |

| Min. distance between longitudinal knives, mm | 22 |

| Min. box height, mm | 18 |

| Types of cardboard | fanfold cardboard |

| Number of places for loading fanfold corrugated cardboard, pcs | 4 |

| Speed of movement of a cross knife, m/min | 60 |

| Speed of movement of longitudinal knives, m/min | 40 |

| Power, kW | 3 |

| Pressure in the pneumatic system, Bar | 6-7 |

| Dimensions (LxWxH), mm | 2500х1300х2500 |

| Weight, kg | 3200 |