Technical Specifications

| Control system | KDT |

| Table size, mm | 3250x1250 |

| Spindle | KDT, 12 kW, 24000 rpm, clamp HSK-63F |

| 4th axis C | KDT |

| drilling head | 12 vertical + 8 horizontal spindles at 6000 rpm + 120 mm grooving saw |

| Tool change | revolving for 16 seats |

| Maximum tool length (excluding workpiece height), mm | 200 |

| Travel speed in X/Y/Z, m/min | 80/40/30 |

| Servo power in X/Y/Z, kW | 1.8/1.3/1.3 |

| Table configuration | 6 vacuum traverses, 18 suction cups SCHMALZ |

| Total power consumption, kW | 24,37 |

| Productivity of vacuum pumps, m3/hour | 1x160 |

| Overall dimensions LxWxH, mm | 5055x3090x2715 |

| Weight, kg | 4000 |

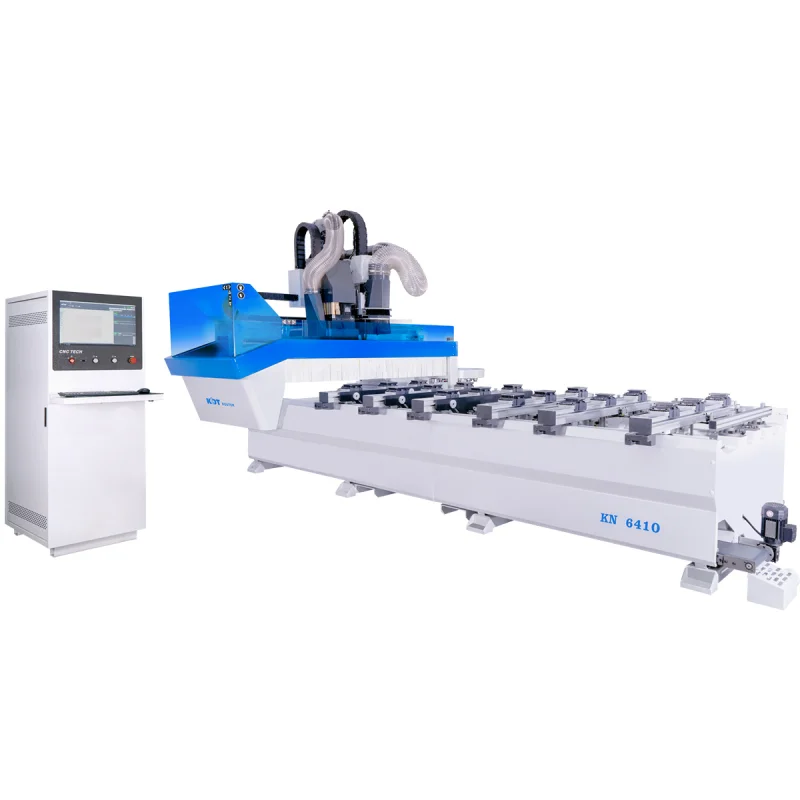

CNC Machining Center KN-6410K 4 Axis

Purpose :

CNC machining center KDT KN-6410K with 4-axis machining with one milling spindle and drilling group (12 vertical spindles + 8 horizontal + grooving saw) is designed for precise, high-speed milling and hole drilling in furniture and carpentry parts products (plywood, furniture board, chipboard, MDF, solid wood of soft and hard breeds). The machine is optimally suited for woodworking and furniture industries that require increased equipment flexibility (Adding holes and milling). It will be useful both in the entry-level enterprise and in large-scale production.

Distinctive features :

Processing area 3250*1250 mm; Table type: Movable traverses "SCHMALZ"; Spindle: KDT - 12 kW with HSK-63F cartridge; Drilling group: 12V+8H+1S; 4th axis - C; Servo motors for moving the portal and spindle along the X/Y/Z axes: - 1.

machine functionality - The machine performs the following operations: three-axis milling (facades, doors, cabinet furniture parts, etc.), inserting holes on five sides and grooving along the X axis with a saw .

4th axis C - Unlike conventional 3-axis milling of a part,4-axis machiningallows you to machine a product from five sides, without additional operations for rearranging the part on the desktop .

kdt control tower - KDT control system- a simple and easy-to-use interface. With various interfaces, the software canbe linked with .xml, .mpr from Homag, .ban, as well as .nc format .

additional control panel - Additional touch-sensitive portable control panel for convenient control of the machine .

machine bed - The bed has the form of a frame structure with stiffening ribs and ceilings made of all-metal sheet, this provides a reliable base for further fastening of all units and assemblies to it .

chip and piece removal conveyor - The machine in the basic configuration has a conveyor for removing chips and small residues of workpieces .

electrospindle kdt - The machine is equipped with an air-cooled KDT electrospindle with a power of 12 kW, a rotation speed of 24,000 rpm, an HSK-63F chuck type, has a high level of reliability and low noise level .

magazine for 16 tools - The 16-station automatic tool changer will provide the machine with the necessary stock of used milling cutters and will allow you to perform complex operations using more tools .

precision cartridge hsk - 63f - Tool and spindle taper HSK 63F The HSK tooling system was developed by German specialists specifically for high-speed and high-precision machining. The use of an HSK taper ensures radial and axial accuracy .

drilling and filler group - Drilling group (12 vertical + 8 horizontal spindles + 1 grooving saw) .

automatic tool measurement and calibration - The sensor of automatic measurement and calibration of the tool makes an accurate measurement of the length of the tool, reduces the setup time of the machine, which greatly facilitates the work of the operator .

additional airflow - Additional blowing of the processing zone ensures effective removal of chips from the cutting zone, which significantly affects the quality of processing and tool life .

hinged screw pair - YZ-axis ball screws - movement is carried out using aTBI ball screw (Taiwan), which guarantees the complete absence of backlash, and subsequently high movement accuracy .

gear rack and pinion - TheSOTERrack and pinion with teeth ground from hardened steel provide high precision and smooth running due to minimal friction and no backlash. The pinion is integrated into a high precision planetary gearbox .

roller guides and carriages - HIWIN (Taiwan) rolling guides and bottom bracketsprovide smooth running due to minimal friction, while maintaining a tight grip and precision accuracy .

delta servomotors and sesam gearboxes - Delta Electronics high power X/Y/Z 1.8/1.3/1.3kW servo motors and SESAME Motor Taiwan precision planetary gearboxes provide synchronous movement, high precision and dynamics .

Desktop - Working table with movable traverses - 6 pieces and vacuum suction cups "SCHMALZ" (Germany) -18 pieces .

pendulum operation - The pendulum mode of operation divides the desktop into two zones - this allows you to set various processing programs in these zones and can significantly reduce the operating time (cycle) of the machine, the time when processing tak .

operator protection - The infrared sensor protection system ensures the safety of the operator while working with the machine .

central lubrication - The automatic lubrication system lubricates all necessary components and assemblies .

electric cabinet - All equipment of the KDT plant uses electrical components from trusted manufacturers. They are interchangeable, thereby increasing the efficiency of service maintenance and quality control .

vacuum system - The vacuum system with a capacity of 160 m3/h securely fixes the workpiece .

Technical Specifications

| Control system | KDT |

| Table size, mm | 3250x1250 |

| Spindle | KDT, 12 kW, 24000 rpm, clamp HSK-63F |

| 4th axis C | KDT |

| drilling head | 12 vertical + 8 horizontal spindles at 6000 rpm + 120 mm grooving saw |

| Tool change | revolving for 16 seats |

| Maximum tool length (excluding workpiece height), mm | 200 |

| Travel speed in X/Y/Z, m/min | 80/40/30 |

| Servo power in X/Y/Z, kW | 1.8/1.3/1.3 |

| Table configuration | 6 vacuum traverses, 18 suction cups SCHMALZ |

| Total power consumption, kW | 24,37 |

| Productivity of vacuum pumps, m3/hour | 1x160 |

| Overall dimensions LxWxH, mm | 5055x3090x2715 |

| Weight, kg | 4000 |