Technical Specifications

| Feed speed, m/min | 15-24 |

| Machine units | 1. Joint joint. 2. Clamping unit. 3. Facing unit. 4. Milling unit for removing overhangs. 5. Contouring unit (rounds). 6. Scraping unit with radius knives. 7. Scraping unit with straight knives. 8. Polishing unit. |

| Minimum part size, mm | 120x95 |

| Edge thickness, mm | 0.4-3 |

| Workpiece thickness, mm | 10-60 |

| Workpiece width, mm | ≥ 95 |

| Workpiece length, mm | ≥ 120 |

| Total power, kW | 21 |

| Working pressure, MPa | 0.6 |

| Dimensions LxWxH, mm | 6200x940x1960 |

| Weight, kg | 2600 |

Automatic edge banding machine KE-706BT

Purpose :

Automatic edge banding machine KE-706BT is designed for simultaneous banding of straight edges of furniture boards and blanks with synthetic roll material. Machine components Joint unit. Clamping unit. Ending unit. Milling unit for removing overhangs. Contouring unit (rounds). Scraping unit with radius knives. Scraping unit with straight knives Polishing unit.

Distinctive features :

Top glue pot with pre-melt with automatic pneumatic loading of granular glue from a special hopper.

machine bed - The bed of the edge banding machine has the form of a rigid box with the necessary stiffening ribs, which guarantees the exact location of all nodes during the entire period of operation .

pc control panel - The machine is controlled by an industrial personal computer with a "Touch screen" system. The on/off icons of units and assemblies on the display are intuitive and do not require special skills to operate the machine .

technological breaks - Possibility of programming technological interruptions of glue pot heating .

rod dispenser - The workpiece feed dispenser rod controls the minimum distance between workpieces, preventing damage to machine components during operation .

Cleansing liquid - A unit for applying a separating liquid using 2 nozzles in front of the pre-milling unit (milling) .

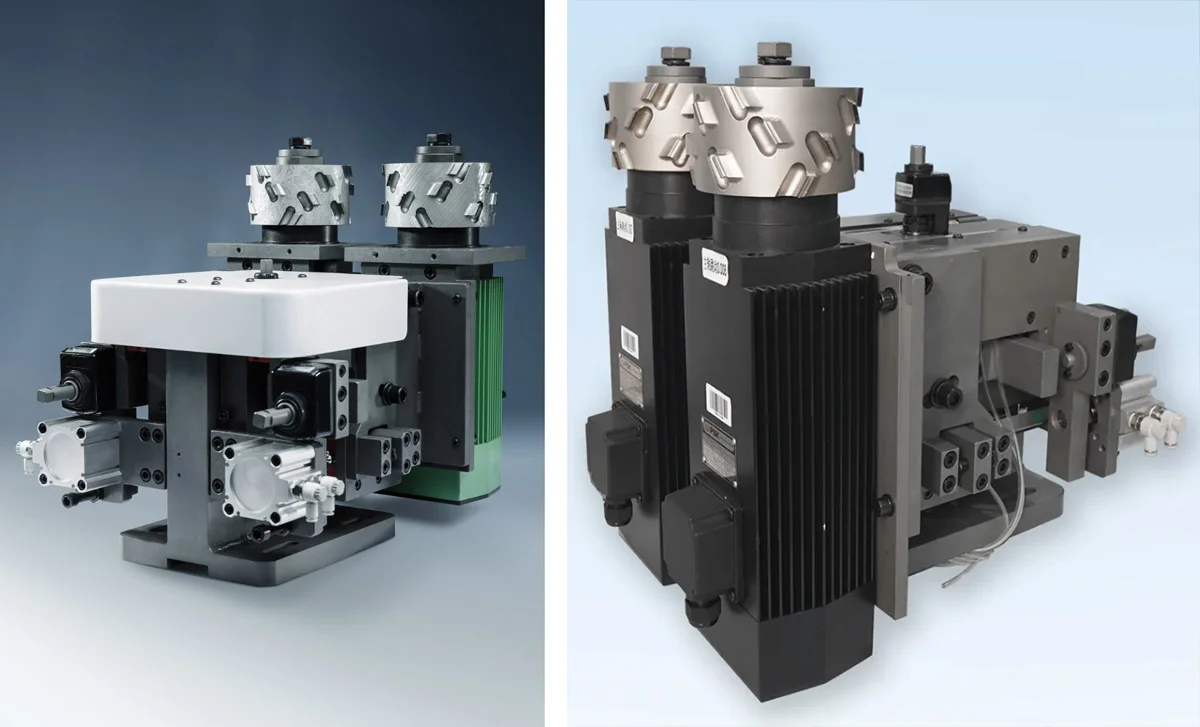

joiner unit - The jointing unit is equipped with two high-frequency motors, which ensures high-quality processing of the end face of the material before gluing the edge. Pre-milling copes with the “step” from the scoring saw, chips .

billet end heating - Preheating the end face of the workpiece for better adhesion .

Edge feed - Independent control of the edge feeding unit .

Clamping unit - The pressure unit consists of 4 rollers, which are driven by pneumatics, which guarantees an even distribution of forces on the edge during gluing .

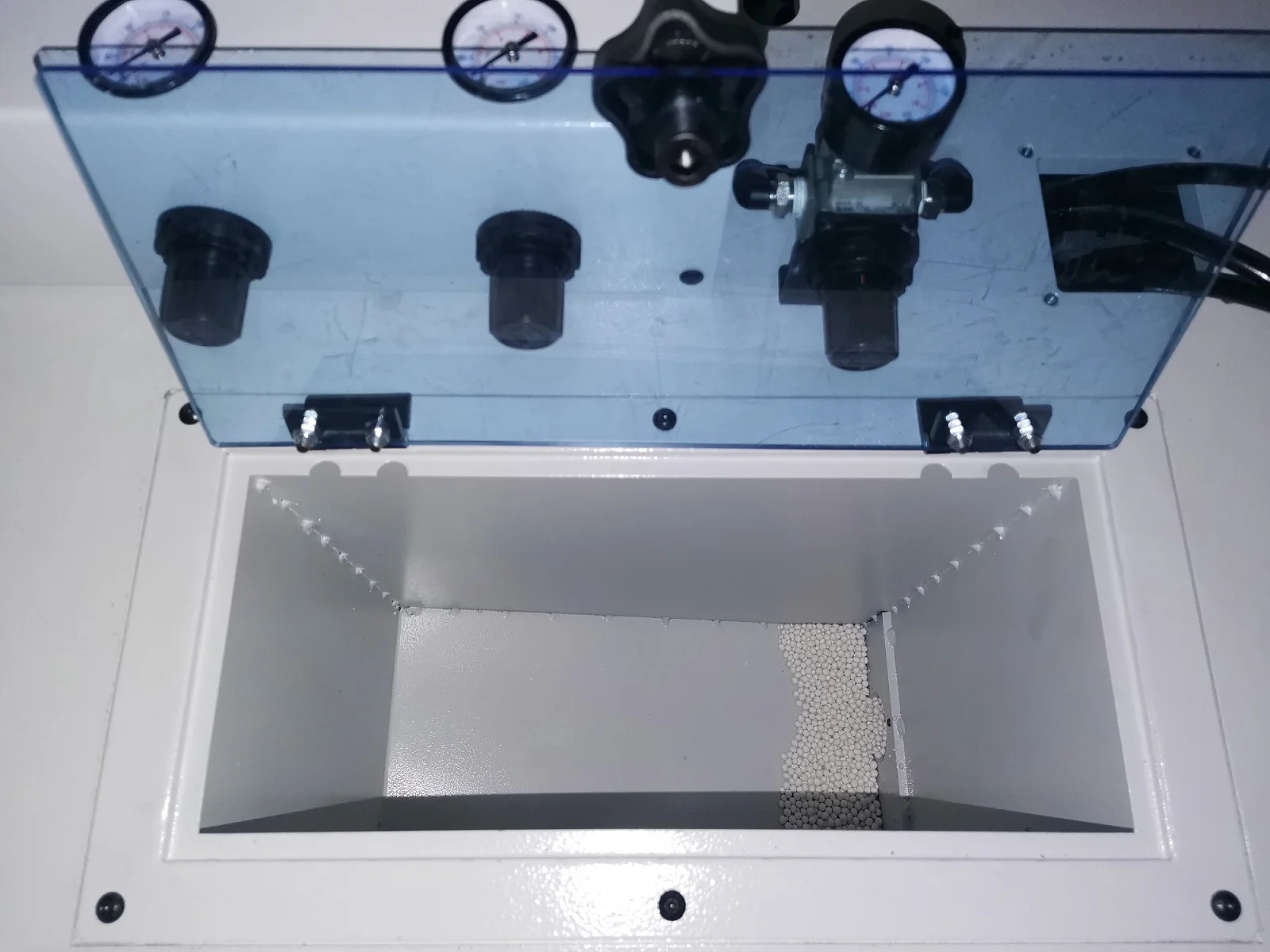

upper glue pot - The machine is equipped with anupper glue pot with a pre-melt of glue, with a capacity of 5 liters. Glue is dosed and does not overheat during machine downtime. The viewing window allows you to control the presence of glue .

glue hopper - The machine is equipped withautomatic pneumatic loading of granulated glue. At the bottom of the machine bed there is a large12.5 kghopper from which, through the air flow, the granules are transported to the upper hopper with pre-melt .

facing unit - The end trimming unit is equipped with two high-frequency electric motors, and the movement of the saw units is carried out along special linear guides .

milling unit - The servo-driven milling unitconsists of two high-frequency electric motors equipped withdiamond radius cutters, which allow processing edge material with a thickness of 0.4 - 3.0 mm .

knot rounds - The rounds (profiling) unit is equipped with two motors and successfully operatesat a speed of 24 m/min. The unit is equipped with diamond radius cutters. There are four schemes of node operation .

radius cycle - The scraping unit on servo drivesis equipped with two hard-alloy radius knives, which, after milling the edge, remove a thin layer from the milled part of the edge and remove the kinematic wave, as a result we get a smooth machined surface .

adhesive scraper - The direct scraping unit is equipped with two hard-alloy straight knives (glue scraper), which carry out edge processing at the joints with the part .

polishing unit - The polishing unit polishesthe processed part of the edge. To give the finishing gloss to the edge, a unit for applying polishing liquid is installed .

Clamping traverse - The encoder on the mechanism for raising/lowering the clamping traverse allows you to automatically position the traverse to the thickness of the part set on the control panel .

Upper belt conveyor - Upper belt conveyor for a secure hold and to prevent contamination and damage to delicate parts .

automatic lubrication of the end assembly - The centralized lubrication unit automatically lubricates the guides of the trimming unit .

Conveyor lubrication - Automatic lubrication of the conveyor is carried out by an electric pump .

electrical components according to CE standard - The electrical components are made in accordance with CE standards .

Operator Protection - The doors of the machine cabin are equipped with special sensors, which allows you to achieve safe work with the equipment .

Noise isolation - The doors of the machine cabin are sheathed with a layer of noise insulation made from foamed polyurethane foam, which allows you to achieve comfortable work with the equipment .

Technical Specifications

| Feed speed, m/min | 15-24 |

| Machine units | 1. Joint joint. 2. Clamping unit. 3. Facing unit. 4. Milling unit for removing overhangs. 5. Contouring unit (rounds). 6. Scraping unit with radius knives. 7. Scraping unit with straight knives. 8. Polishing unit. |

| Minimum part size, mm | 120x95 |

| Edge thickness, mm | 0.4-3 |

| Workpiece thickness, mm | 10-60 |

| Workpiece width, mm | ≥ 95 |

| Workpiece length, mm | ≥ 120 |

| Total power, kW | 21 |

| Working pressure, MPa | 0.6 |

| Dimensions LxWxH, mm | 6200x940x1960 |

| Weight, kg | 2600 |