Technical Specifications

| Feed speed, m/min | 22-30 |

| Machine units | 1. Joint joint. 2. Clamping unit. 3. Facing unit. 4. The first milling unit for removing overhangs. 5. The second milling unit for removing overhangs. 6. Node contouring (rounds). 7. The first scraping unit with radius knives. 8. The second scraping unit with radius knives. 9. Scraping unit with straight knives. 10. First polishing unit. 11. Second polishing unit. |

| Minimum part size, mm | 100x60 |

| Edge thickness, mm | 0,4-3 |

| Workpiece thickness, mm | 9-60 |

| Workpiece width, mm | ≥ 60 |

| Workpiece length, mm | ≥ 100 |

| Total power, kW | 41 |

| Working pressure, MPa | 0.6 |

| Dimensions LxWxH, mm | 11889x11150x1960 |

| Weight, kg | 4500 |

Automatic Edge Banding Machine KE-526G

Purpose :

The high-speed automatic edge banding machine KE-526G of the pass-through type is designed for simultaneous lining of straight edges of furniture panels and blanks with synthetic roll material. Machine components Jointing unit. Clamping unit. Facing unit. The first milling unit for removing overhangs. Second milling unit for removing overhangs. Contouring unit (rounds). The first scraping unit with radius knives. The second scraping unit with radius knives. Scraping unit with straight knives First polishing unit. Second polishing unit.

Distinctive features :

High feed speed 22-30 m/min; Two upper glue baths for working with EVA and PUR glue; Edge feed magazine for 6+6 positions with servo drive; Pneumatic adjustment to different edge thicknesses from the control panel; A pressure tape instead of rollers guarantees precise positioning of the part at all stages of edge processing at a speed of 30 m/min; Horizontal facing unit; 4-motor unit rounds; Pressing group for 7 rollers with scrapers; “Touch screen” control panel based on WINDOWS 10; Additional pressure rollers; Built-in waypoint control for non-contact control of processing units; Possibility of programming technological breaks of the glue bath; High precision counters; The ability to automatically reconfigure the traverse to the size set on the control panel using an encoder has been implemented.

machine bed - The bed of the edgebanding machine has the shape of a rigid box with the necessary stiffening ribs, which guarantees the exact location of all components throughout the entire service life .

PC control panel - The machine is controlled using an industrialpersonal computerbased on WINDOWS 10 with the Touch screen system .

technological breaks - Possibility of programming technological breaks in heating the glue bath .

edge feed - An edge feed magazine with 6+6 positions with a servo drivefor automatically changing one edge to another - ease of operation, saving time and labor costs .

jointing unit - The jointing unit is equipped with two high-frequency motors, which ensures high-quality processing of the end of the material before gluing the edge. Pre-milling copes with the “step” from the scoring saw and chips .

heating the end of the workpiece - Preheating of the workpiece end for better adhesion .

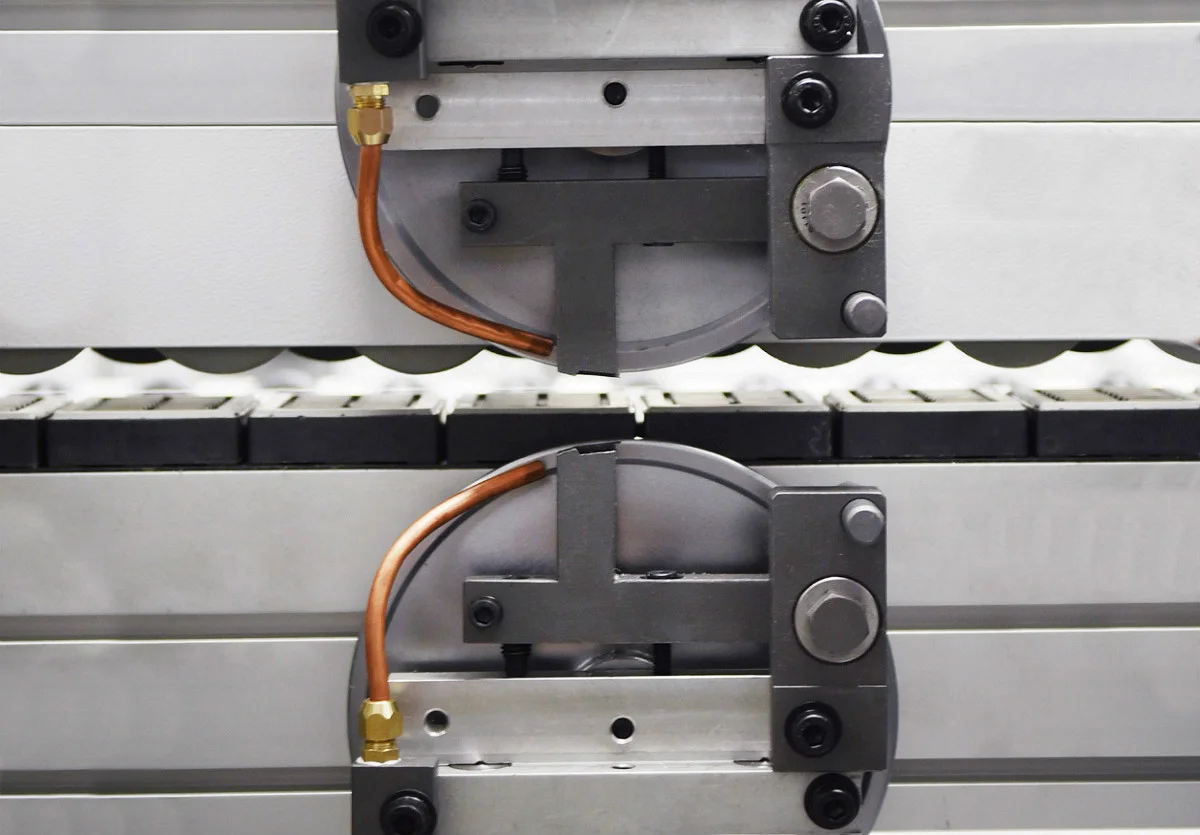

Clamping unit - The pressure unit consists of 7 rollers with scrapers to remove excess glue and are driven by pneumatics, which guarantees uniform distribution of forces on the edge during gluing .

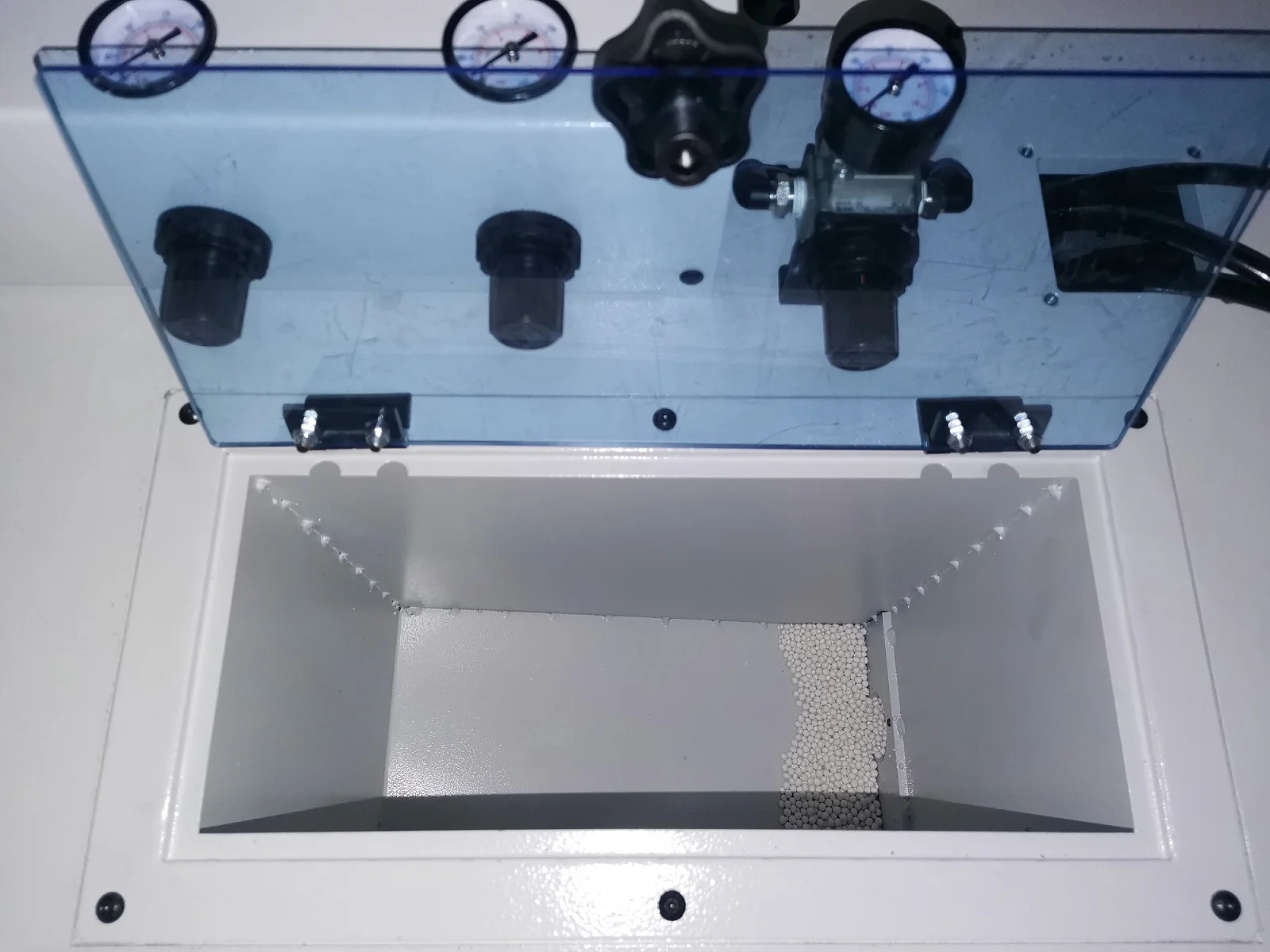

upper glue bath - The machine is equipped with two upper glue baths: onefor EVA gluewith pre-melt glue, with a capacity of 5 liters, and the second sealed forPUR glue .

glue bin - The machine is equipped withautomatic pneumatic loading of granular glue. A large12.5 kghopper is installed at the bottom of the machine frame, from which, through an air flow, the granules are transported to the upper hopper with pre-melt .

trimming unit - The horizontal facing unitensures precise processing of edge overhangs at the ends of the workpiece and allows you to reduce the distance between workpieces at a speedof up to 30 m/min.Automatic saw angle adjustment .

milling unit - The milling unit consists of two high-frequency electric motors equipped withdiamond radius cutters, which allow processing edge material with a thickness of 0.4 - 3.0 mm .

rounds node - The rounding (contouring) unit is equipped with four high-speed motors and operates successfully at a speed of 30 m/min. The unit is equipped with diamond radius cutters. There are four possible operation schemes for the unit .

radius cycle - The first and second scraping units are equipped with two carbide radius knives, which, after milling the edge, remove a thin layer from the milled part of the edge and remove the kinematic wave, as a result we get a smooth processed surfac .

flat scraper - Radius scraping units are equipped with mechanisms for pneumatic adjustment from a remote control to another thickness of edge and a mechanism for dividing edge residues along the length for more efficient removal .

glue scraper - The direct scraping unit is equipped with two carbide straight knives (glue scraper), which process the edges at the joints with the part .

polishing unit - A double polishing unitpolishes the processed part of the edge; high quality is achieved through an oscillation system driven by pneumatic cylinders. To impart a final shine to the edge, a unit for applying polishing liquid is installed .

setting up nodes with counters - High-precision adjustment counter on machine components .

pressure tape - The steel clamping beam with V-shaped clamping beltguarantees precise and reliable positioning of the workpiece during all stages of edge processing at a speed of 30 m/min .

additional pressure rollers - Additional pressure rollers guarantee reliable fixation of the workpiece .

encoder - The encoder on the mechanism for raising/lowering the clamping beam allows you to automatically position the crossarm to the thickness of the part set on the control panel .

automatic lubrication of the end assembly - The centralized lubrication unit automatically lubricates the guides of the trimming unit .

electrical components according to CE standard - Electrical components are made in accordance with CE standards .

Technical Specifications

| Feed speed, m/min | 22-30 |

| Machine units | 1. Joint joint. 2. Clamping unit. 3. Facing unit. 4. The first milling unit for removing overhangs. 5. The second milling unit for removing overhangs. 6. Node contouring (rounds). 7. The first scraping unit with radius knives. 8. The second scraping unit with radius knives. 9. Scraping unit with straight knives. 10. First polishing unit. 11. Second polishing unit. |

| Minimum part size, mm | 100x60 |

| Edge thickness, mm | 0,4-3 |

| Workpiece thickness, mm | 9-60 |

| Workpiece width, mm | ≥ 60 |

| Workpiece length, mm | ≥ 100 |

| Total power, kW | 41 |

| Working pressure, MPa | 0.6 |

| Dimensions LxWxH, mm | 11889x11150x1960 |

| Weight, kg | 4500 |