Technical Specifications

| Feed speed, m/min | 15-23 |

| Machine units | 1. Joint joint. 2. Clamping unit. 3. Facing knot. 4. Milling unit for removing overhangs. 5. Scraping unit with radius knives. 6. Scraping unit with straight knives. 7. Polishing unit. |

| Minimum part size, mm | 120x80 |

| Edge thickness, mm | 0.4-3 |

| Workpiece thickness, mm | 10-60 |

| Workpiece width, mm | ≥ 80 |

| Workpiece length, mm | ≥ 120 |

| Total power, kW | 16.05 |

| Working pressure, MPa | 0.6 |

| Dimensions LxWxH, mm | 5346x830x1720 |

| Weight, kg | 1900 |

Automatic edge banding machine KE-655JSMA

Purpose :

The KE-655JSMA automatic edge banding machine of the pass-through type with pneumatic permutation of nodes and an upper glue bath without premelting is designed for simultaneous veneering of straight edges of furniture boards and blanks with synthetic roll material. Machine components Joint knot. Clamping knot. Ending knot. Milling unit for removing overhangs. Scraping unit with radius knives. Scraping unit with straight blades. polishing unit.

Distinctive features :

Feed speed 15-23 m/min; Top glue bath without premelt ; Automatic changeover to 2 different edge thicknesses by quickly pressing the corresponding button on the machine control screen; Automatic changeover to 4 different workpiece thicknesses by quickly pressing the corresponding button on the machine control screen (with memory); Infrared lamp for heating the end face of the workpiece; Conveyor feed with encoder system; edge counter; Reinforced conveyor; 5 pressure rollers with scrapers; Pneumatic mechanism for removing scraping chips from the workpiece; Two units with cleaning liquid - one in front of the jointing unit and the second in front of the polishing unit; Control panel "Touch screen"; Built-in waypoint control for non-contact control of processing units; Possibility of programming technological breaks; Individual frequency converter for each working node; Lighting in the protective cabin; Limit switches on the doors in the protective cabin; Stock dispenser rod prevents damage to machine components during operation; Pneumatic shutter on the glue roller, prevents it from getting dirty; Adjustment of the front and rear overhangs of the edge from the control panel; Execution according to CE standards.

top glue bath without premelt - Topglue pot without pre-melting gluewith non-stick coating .

machine bed - The bed of the edge banding machine has the form of a rigid box with the necessary stiffening ribs, which guarantees the exact location of all nodes during the entire period of operation .

Remote Control - The machine is controlled using a special remote control equipped with an industrial display with a “Touch screen” system .

technological breaks - Possibility of programming technological interruptions of glue bath heating .

shoe guide - The wall thickness of the conveyor guide shoes has been increased to 15 mm .

rod dispenser - The workpiece feed dispenser rod controls the minimum distance between workpieces, preventing damage to machine components during operation .

steel columns of the upper pressure beam - The new design of the upper beam columns of increased rigidity and special geometry, developed by the engineers of the KDT plant, provides high strength support .

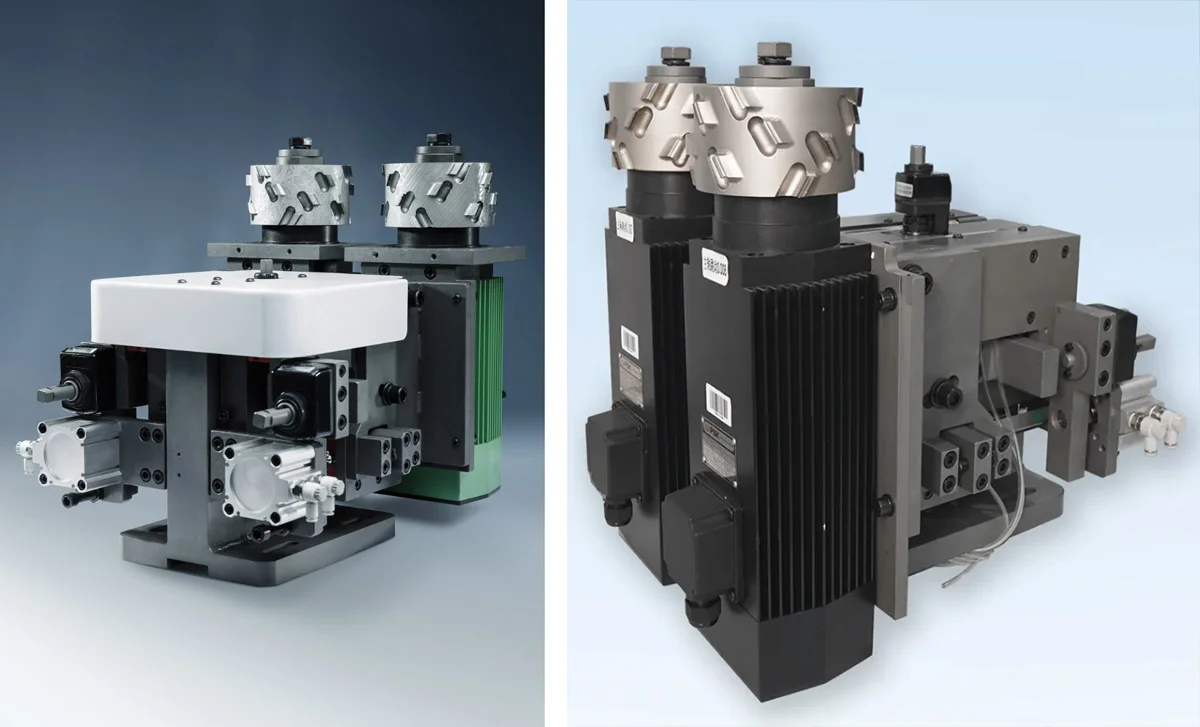

joiner unit - The jointing unit is equipped with two high-frequency motors, which ensures high-quality processing of the end face of the material before gluing the edge. Pre-milling copes with the “step” from the scoring saw, chips .

billet end heating - Preheating the end face of the workpiece for better adhesion .

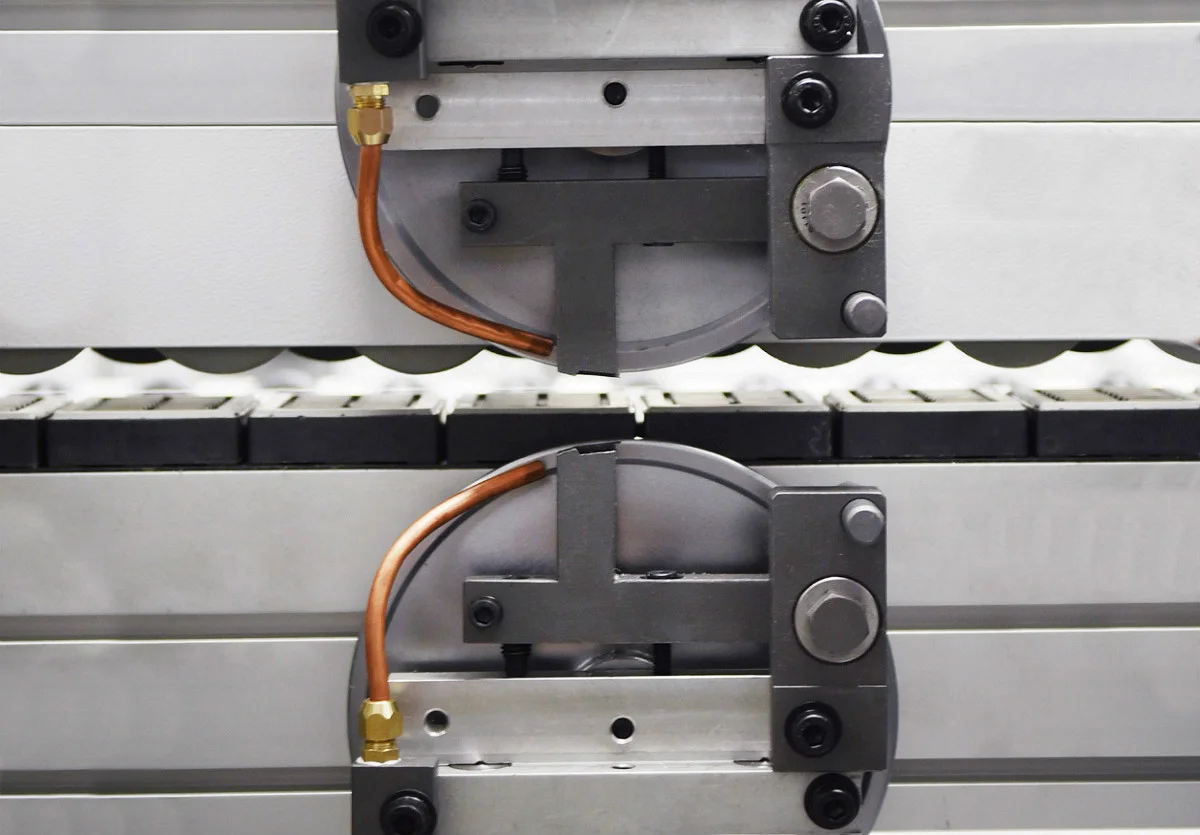

Clamping unit - The pressing unit consists of 5 rollers, which are driven by pneumatics, which guarantees an even distribution of forces on the edge during gluing .

facing unit - The end trimming unit is equipped with two high-frequency electric motors, and the movement of the saw units is carried out along special linear guides .

milling unit - The milling unit consists of two high-frequency electric motors equipped with radius cutters, which allow processing edge material with a thickness of 0.4 - 3.0 mm .

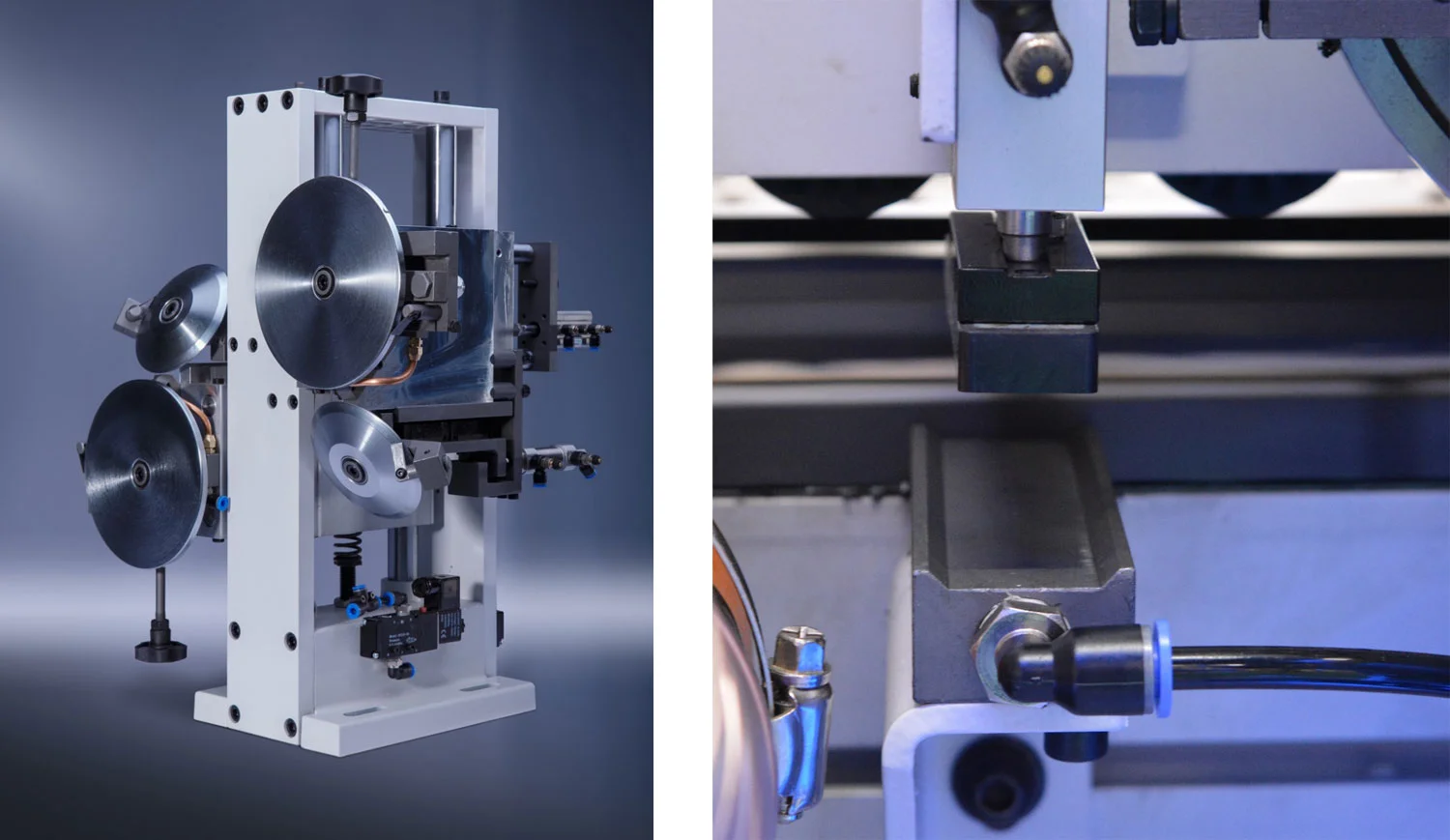

radius cycle - Radial scraping with two carbide radius knives, which, after milling a 2.0 mm thick edge, remove a thin layer from the milled part of the edge, as a result we get a smooth machined surface .

flat cycle - The direct scraping unit is equipped with two hard-alloy straight knives (glue scraper), which carry out edge processing at the joints with the part .

polishing unit - The polishing unit polishes the processed part of the edge. For safety, the unit is equipped with additional protective covers .

clamping traverse - The mechanism for lifting/lowering the clamping traverse is equipped with an electric drive, which ensures fast and accurate installation to the required thickness of the part .

automatic lubrication of the end assembly - The centralized lubrication unit automatically lubricates the guides of the trimming unit .

electrical components according to CE standard - Electrical components of the world's leading manufacturer, Siemens, are made in accordance with CE standards .

Noise isolation - The doors of the machine cabin are sheathed with a layer of noise insulation made from foamed polyurethane foam, which allows you to achieve comfortable work with the equipment .

Technical Specifications

| Feed speed, m/min | 15-23 |

| Machine units | 1. Joint joint. 2. Clamping unit. 3. Facing knot. 4. Milling unit for removing overhangs. 5. Scraping unit with radius knives. 6. Scraping unit with straight knives. 7. Polishing unit. |

| Minimum part size, mm | 120x80 |

| Edge thickness, mm | 0.4-3 |

| Workpiece thickness, mm | 10-60 |

| Workpiece width, mm | ≥ 80 |

| Workpiece length, mm | ≥ 120 |

| Total power, kW | 16.05 |

| Working pressure, MPa | 0.6 |

| Dimensions LxWxH, mm | 5346x830x1720 |

| Weight, kg | 1900 |