Technical Specifications

| Maximum material dimensions at front loading, mm | 4300x4300 |

| Maximum material dimensions at rear loading, mm | 2100x4000 |

| Minimum grip dimensions when sawing, mm | 34x45 |

| Maximum cutting thickness, mm | 120 |

| Saw carriage travel speed, m/min | 120 |

| Saw carriage idle speed, m/min | 150 |

| Pusher speed, m/min | 95 |

| Main saw diameter, mm | 450/75 |

| Scoring saw diameter, mm | 200/50 |

| Main saw drive power, kW | 18.5 |

| Scoring saw drive power, kW | 2.2 |

| Programmable pusher drive power, kW | 2 |

| Saw carriage drive power, kW | 2 |

| Gripper amount | 5 + Twin Pusher + 2 movable group grippers |

| Installed power, kW | 51 |

| Pneumatic system working pressure, MPa | 0.6 |

| Overall dimensions LxWxH, mm | 12970x7570x2030 |

| Weight, kg | 11000 |

CNC panel saw/beam saw KS-843HLM

Purpose :

CNC panel saw KS-843HLM with rear loading and double pusher (the size of the package to be cut at front loading is 4300*4300 mm, at the rear - 2100*4000 mm) is designed for cutting a package of board materials (chipboard, MDF, fiberboard, etc. .), both lined and unlined. The machine is used in the conditions of large-scale and mass production for the manufacture of cabinet furniture, furniture panels, molded products. Rear loading simplifies the logistics of materials in production and facilitates the work of machine operators. Processing scheme

Distinctive features :

Work with optimizer programs that allow programming the cutting sequence, printing labels and importing files with cutting maps; Automatic rear loading on the machine allows you to load a package with a maximum size of 2100x4000 mm; 2 independent pushers for cutting panels with different lengths, improve cutting efficiency at different sizes; Moves the two left grips parallel to the cutting line; Magnetic positioning to measure the lifting of the workpiece from the rear load, the minimum thickness of the workpiece is 8mm; The maximum height of the opened package is 120 mm; The movement of the saw carriage occurs due to the spur rack and gear with the help of a servomotor.

automatic rear loading - Automatic rear loading allows you to load a package with a maximum size of4000x2100 mminto the machine. The table is raised hydraulically, which guarantees smooth running and stable operation .

workpiece magnetic positioning - Magnetic positioning to measure workpiece lift from back load, minimum workpiece thickness is 8mm .

2 independent pushers - 2 independent pushers for cutting panels with different lengths,improve cutting efficiency at different sizes .

sheet feeding - The next sheet is fed before the cutting of the current one is completed .

cutting two different blanks - The machine can carry out simultaneous cutting of two blanks of different sizes .

programmable pusher - Moves the two left grips parallel to the cutting line to prevent damage to the edges of parts and securely hold parts of different widths .

powerful machine bed - The machine bed was developed taking into account CAD programs, where the maximum allowable loads and requirements for the machine design were calculated and simulated .

PC machine control - An industrial computer based on Windows 10 ensures reliable operation of the CNC system .

work visualization - Visualization of the order of cutting and a schematic map of the cut .

cutting optimizer - Ability to work with all popular programs for optimizing cutting charts and printing labels .

Longitudinal lever - Longitudinal lever for switching on/off the cutting cycle .

large main desktop - The main working table is increased to 2200*800 mm .

work tables with air cushion for workpiece feeding - Four air-cushioned worktables allow the operator to effortlessly position the stack of materials and remove finished parts from the machine .

cut zone - Air cushion tables are installed in the cutting area, which greatly facilitates the work with small parts and protects them from damage .

individual engines - Separate motors for main and scoring saw .

saw blade height - Automatic adjustment of the height of the main saw and the departure of the pressure beam according to the height of the package being cut .

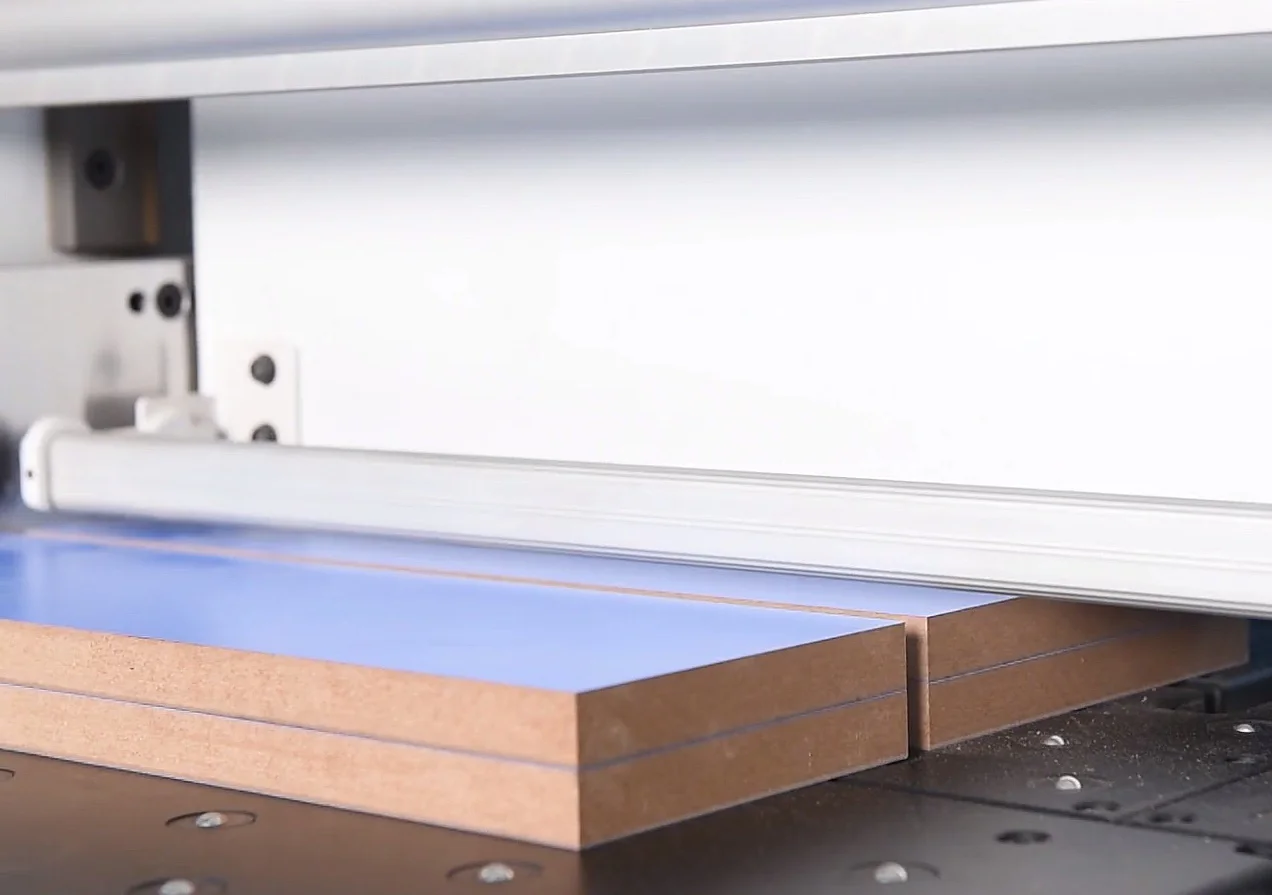

pressure beam - The force of the clamping beam is controlled by the system and corresponds to the thickness or height of the stack cutting. Equipped with an injury protection system .

saw carriage movement - The movement of the saw carriage occurs due to a spur rack and gear using a servomotor. This ensures greater cutting accuracy up to +-0.1 mm .

side clamps for workpiece alignment - Side stops precisely position narrow strips along the side ruler when cutting them into finished parts .

special grip design - The special design of the grippers does not damage the material during its fixation and movement .

flexible cable channel - Flexible and durable cable channel provides stable and fast movement of the pusher with pneumatic grips .

electrical components - Electrical components comply with CE standards .

minimum workpiece size - The minimum workpiece size is 34*45 mm .

Technical Specifications

| Maximum material dimensions at front loading, mm | 4300x4300 |

| Maximum material dimensions at rear loading, mm | 2100x4000 |

| Minimum grip dimensions when sawing, mm | 34x45 |

| Maximum cutting thickness, mm | 120 |

| Saw carriage travel speed, m/min | 120 |

| Saw carriage idle speed, m/min | 150 |

| Pusher speed, m/min | 95 |

| Main saw diameter, mm | 450/75 |

| Scoring saw diameter, mm | 200/50 |

| Main saw drive power, kW | 18.5 |

| Scoring saw drive power, kW | 2.2 |

| Programmable pusher drive power, kW | 2 |

| Saw carriage drive power, kW | 2 |

| Gripper amount | 5 + Twin Pusher + 2 movable group grippers |

| Installed power, kW | 51 |

| Pneumatic system working pressure, MPa | 0.6 |

| Overall dimensions LxWxH, mm | 12970x7570x2030 |

| Weight, kg | 11000 |