Technical Specifications

| Maximum cutting length, mm | 3100 |

| Maximum cutting width, mm | 3200 |

| Minimum grip dimensions when sawing, mm | 34x45 |

| Maximum cutting thickness, mm | 90 |

| Saw carriage travel speed, m/min | 95 |

| Saw carriage idle speed, m/min | 120 |

| Pusher speed, m/min | 95 |

| Main saw diameter, mm | 400/450(option) x75 |

| Scoring saw diameter, mm | 200/50 |

| Main saw drive power, kW | 18.5 |

| Scoring saw drive power, kW | 2.2 |

| Programmable pusher drive power, kW | 2 |

| Saw carriage drive power, kW | 2 |

| Gripper amount | 8 |

| Installed power, kW | 35 |

| Pneumatic system working pressure, MPa | 0.6 |

| Overall dimensions LxWxH, mm | 7750х5495х2030 |

| Weight, kg | 6000 |

CNC panel saw/beam saw KS-832HT

Purpose :

CNC panel saw/beam saw KS-832HT with a double pusher (the size of the cut package is 3100*3200 mm) is designed for cutting a package of board materials (chipboard, MDF, fiberboard, etc.), both lined and unlined. The machine is used in the conditions of large-scale and mass production for the manufacture of cabinet furniture, furniture panels, molded products. Processing scheme

Distinctive features :

Work with optimizer programs that allow programming the cutting sequence, printing labels and importing files with cutting maps; 2 independent pushers for cutting panels with different lengths, improve cutting efficiency at different sizes; Grooving function; Polished steel plates in the cutting area; The maximum height of the opened package is 90 mm; The movement of the saw carriage occurs due to a spur rack and gear using a servomotor.

2 independent pushers - 2 independent pushers for cutting panels with different lengths, improve cutting efficiency at different sizes .

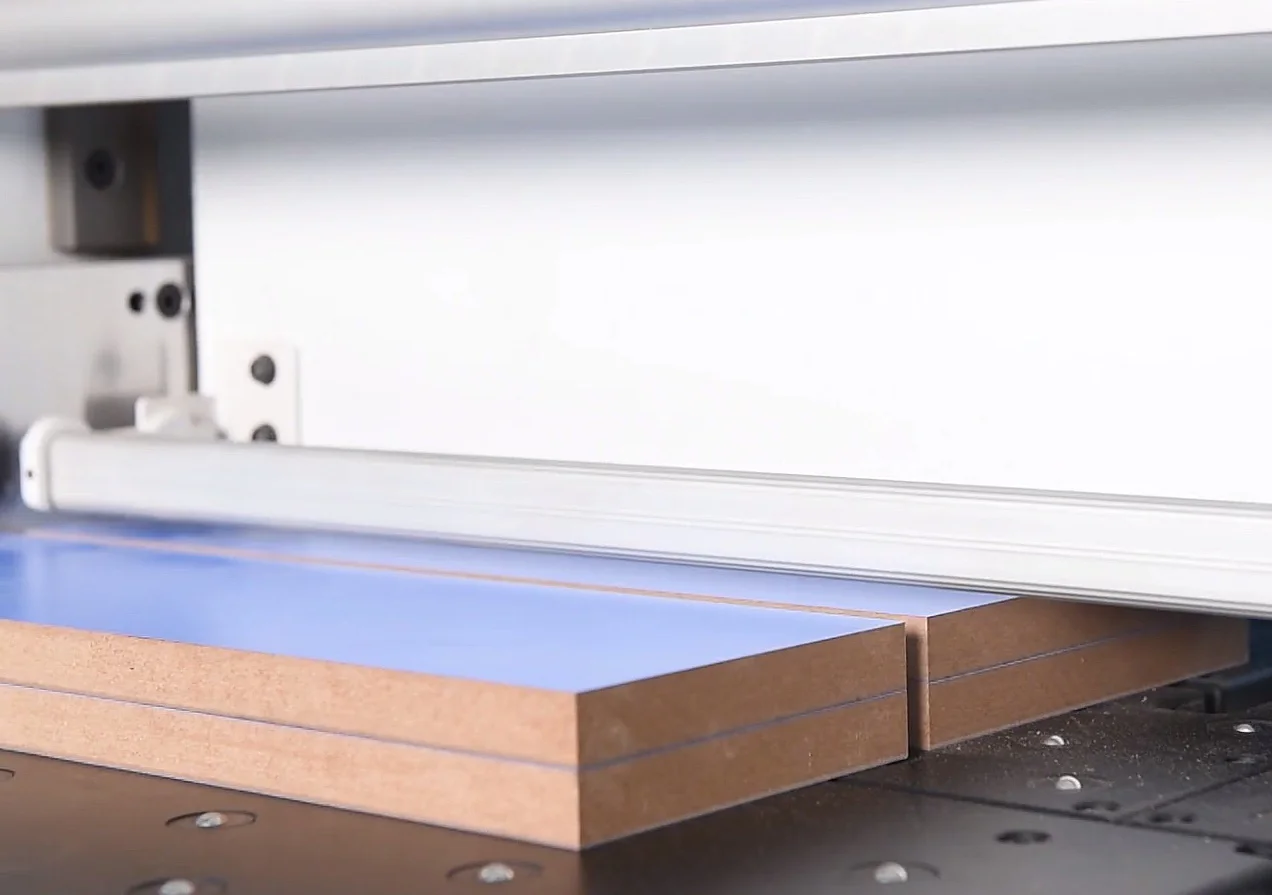

cutting two different blanks - The machine can carry out simultaneous cutting of two blanks of different sizes .

grooving function - Groove function. The lifting of the main saw is carried out by a servo drive, due to which a high accuracy of the cutting height is achieved .

powerful machine bed - The machine bed was developed taking into account CAD programs, where the maximum allowable loads and requirements for the machine design were calculated and simulated .

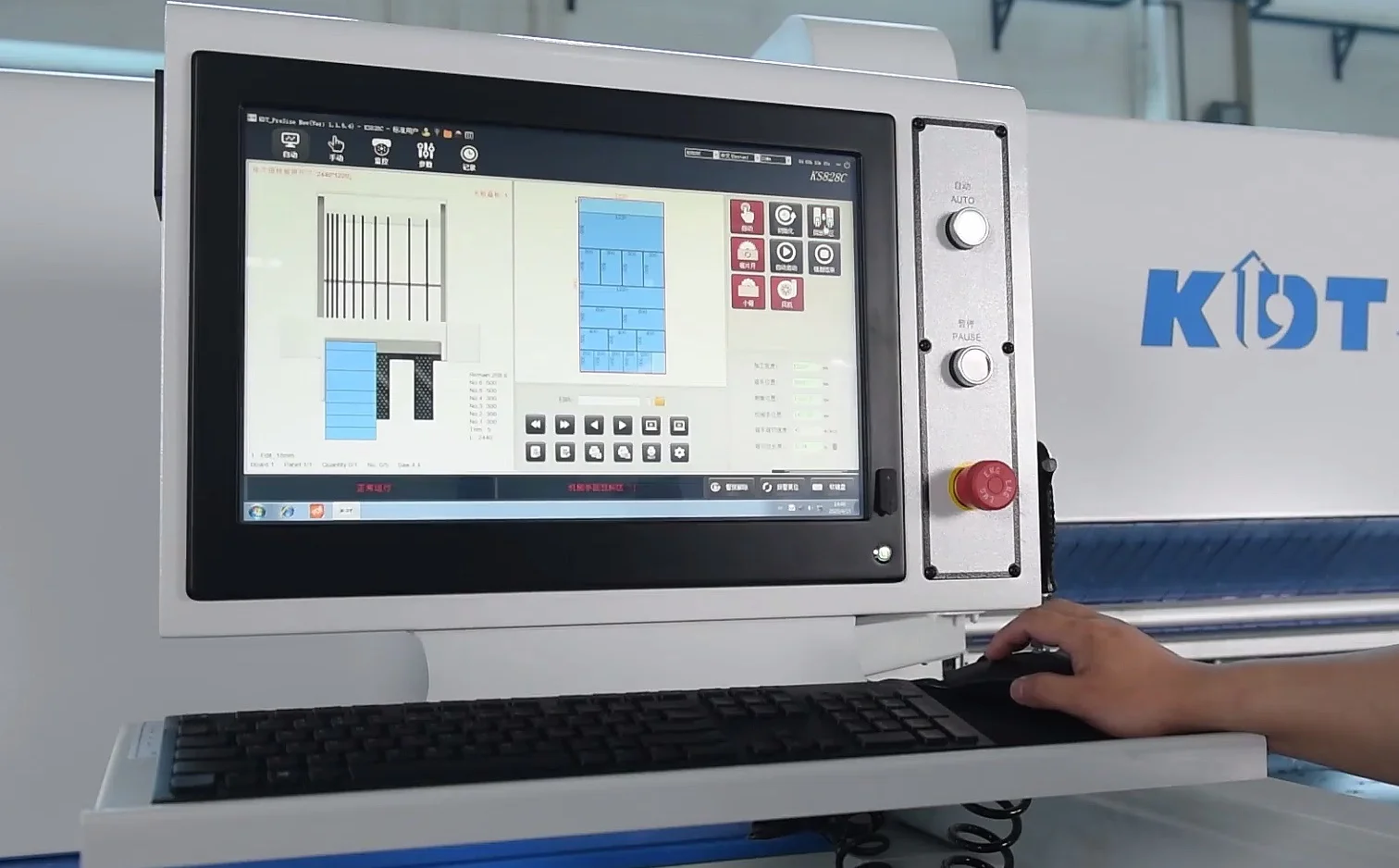

PC machine control - An industrial computer based on Windows 10 ensures reliable operation of the CNC system .

cutting optimizer - Ability to work with all popular programs for optimizing cutting charts and printing labels .

Longitudinal lever - Longitudinal lever for switching on/off the cutting cycle .

air cushion work tables - The working tables are equipped with an air cushion system to facilitate the positioning of workpieces .

cut zone - The cutting area is equipped with tables with polished steel plates with an air cushion, which significantly facilitates work with small parts and protects them from damage .

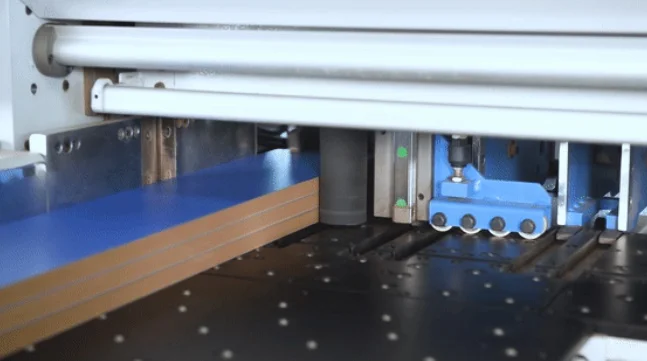

individual engines - Separate motors for main and scoring saw. Servo adjustment for lifting/lowering the main saw .

saw blade height - Automatic adjustment of the height of the main saw and the departure of the pressure beam according to the height of the package being cut .

pressure beam - The force of the clamping beam is controlled by the system and corresponds to the thickness or height of the stack cutting. Equipped with an injury protection system .

saw carriage movement - The movement of the saw carriage occurs due to a spur rack and gear using a servomotor. This ensures greater cutting accuracy up to +-0.1 mm .

side clamps for workpiece alignment - Side stops with rollers and linear guide accurately position narrow strips on the side ruler when cutting them into finished parts and ensure more stable operation .

programmable pusher - The programmable pusher is equipped with eight two-finger pneumatic grippers, which guarantees a secure fixation of the workpiece package.Eightgrippers securely fix both a package of material up to 90 mm thick and one sheet .

special grip design - The special design of the grippers does not damage the material during its fixation and movement .

flexible cable channel - Flexible and durable cable channel provides stable and fast movement of the pusher with pneumatic grips .

electrical components - Electrical components comply with CE standards .

minimum workpiece size - The minimum workpiece size is 34*45 mm .

Technical Specifications

| Maximum cutting length, mm | 3100 |

| Maximum cutting width, mm | 3200 |

| Minimum grip dimensions when sawing, mm | 34x45 |

| Maximum cutting thickness, mm | 90 |

| Saw carriage travel speed, m/min | 95 |

| Saw carriage idle speed, m/min | 120 |

| Pusher speed, m/min | 95 |

| Main saw diameter, mm | 400/450(option) x75 |

| Scoring saw diameter, mm | 200/50 |

| Main saw drive power, kW | 18.5 |

| Scoring saw drive power, kW | 2.2 |

| Programmable pusher drive power, kW | 2 |

| Saw carriage drive power, kW | 2 |

| Gripper amount | 8 |

| Installed power, kW | 35 |

| Pneumatic system working pressure, MPa | 0.6 |

| Overall dimensions LxWxH, mm | 7750х5495х2030 |

| Weight, kg | 6000 |